Worm gearboxes from b-drives

– cost-effective & self-locking angular gearboxes

Basics – Introduction & How it works

What is a worm gear?

A worm gear is a special angular gear consisting of a worm (screw) and a worm wheel (gear wheel). This design enables high reduction ratios in a single stage, very smooth running and, depending on the version, self-locking, which prevents unwanted reverse movement. In addition, the force is transmitted at a 90° angle, which is useful for the installation space in many applications.

How does a worm gearbox work?

A worm gearbox uses a worm (a helical shaft) that drives the worm wheel. The movement takes place via sliding friction, which makes operation very quiet.

Typical areas of application for worm gearboxes

Worm gearboxes are used for applications that require high reduction ratios, compact design and self-locking properties.

Drive systems for conveyor belts and lifting systems

precise movements with high reduction ratio

Stainless steel variants for hygienic applications

What worm gearboxes does b-drives offer?

Worm gearboxes are used for applications that require high reduction ratios, compact design and self-locking properties.

Standard worm gearboxes

- • Sizes: 20 to 150 mm centre distance

- • Translations: 5:1 to 80:1

Worm gear with hand crank

- • Perfect for manual adjustment mechanisms

Stainless steel worm gear

- • Ideal for food, pharmaceutical and medical technology

Rotary table with worm gear drive

- • For heavy loads and positioning systems

Advantages & limitations of worm gearboxes at a glance

What are the advantages of a worm gear?

- High reduction ratio possible in just one stage

- Self-locking – prevents unwanted back rotation

- Very economical due to the small number of components

What are the disadvantages of worm gears?

- Lower efficiency than other gearboxes

- Self-locking only from approx. i = 30:1

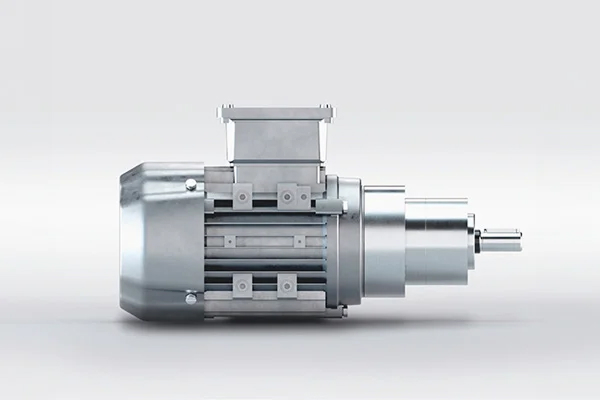

Our motors for worm gearboxes

AC asynchronous motors

• Power range: 0.06 to 355 kW

• Efficiency classes: IE2, IE3, IE4

Frequently asked questions about worm gearboxes

What is a worm gear?

Where are worm gears typically used?

Worm gearboxes are used for applications that require high reduction ratios, compact design and self-locking properties.

Typical industries and areas of application:

- Conveyor technology – drive systems for conveyor belts and lifting systems

- Packaging machines – precise movements with high reduction ratios

- Food industry – stainless steel variants for hygienic applications

What are the main advantages of worm gears?

- High reduction ratio possible in just one stage

- Self-locking – prevents unwanted back rotation

- Relatively quiet due to the few interlocking parts and the sliding friction principle

- Very economical due to the low number of toothed parts

What factors should I consider when selecting a worm gear?

Efficiency: The higher the reduction ratio, the lower the efficiency

Lubrication: Oil lubrication recommended for long operation

Self-locking: Possible from approx. 30:1

We will be happy to answer any questions you may have and look forward to hearing from you.

You can reach us Mon – Thu from 8 am to 5 pm and Fri from 8 am to 2 pm.