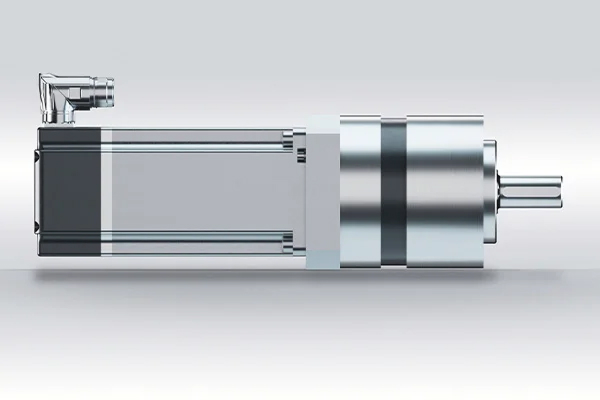

High-precision servomotors for industry and automation

Future-proof drive solutions for the highest demands in industrial engineering.

Powerful drive solutions for demanding motion sequences

From 42 mm to 260 mm

Up to IP65

From 60V DC to 400V AC

From 10W to 3 kW

Precise control for the highest demands

Servomotors enable precise control of position, speed and torque. They consist of a motor with a position sensor and control electronics (servo controller) that operates in a closed control loop. This enables highly dynamic and precise motion sequences in industrial applications.

Precise positioning to a fraction of a millimeter

Precise control from standstill to maximum speed

Precise force control for sensitive processes

Fast response behavior and short reaction times

Applications for our servomotors

Servomotors from b-drives are used in numerous industrial sectors:

Precise motion control for robot arms.

Precise control for manufacturing processes.

High dynamics for industrial applications.

Reliable drives for material handling.

Precise control for sensitive devices.

Frequently asked questions about servo motors

What is a servomotor?

A servomotor is an electric drive that is used for precise motion control. It usually consists of a motor, a sensor for position detection and a control loop (e.g. via a servo controller). Servomotors are characterized by precise positioning, high torque with small sizes and fast response times.

How does a servomotor work?

A sensor continuously measures the current position of the motor. The actual position is compared with the target position via a feedback loop (closed-loop system). Deviations are corrected immediately – resulting in a highly dynamic and precise movement, even for complex processes.

In which areas are servomotors used?

Servomotors are used in a wide variety of industries:

– Robotics: For precise control of joints and motion axes

– Automation technology: In pick-and-place applications, production lines, packaging systems

– Medical technology: For precise control in surgical devices or diagnostic systems

– Production technology: In CNC machines, machine tools, conveyor technology

– Printing and textile industry: For synchronized motion sequences

– Aerospace: In positioning mechanisms and position control systems

What is the difference between a servo motor and a normal electric motor?

The main difference lies in the regulation:

– Servomotor: Integrated feedback via sensors (closed-loop), extremely precise positioning

– Standard motor: No feedback (open-loop), simple rotary movement without control

Servomotors are specially designed for dynamic and controllable applications where accuracy is crucial.

What are the advantages of a servomotor?

– Highest precision in position, speed and torque

– Fast response time

– Compact design with high power density

– Reliability in continuous operation

– Flexible integration into modern control systems

– Low-noise operation

How is a servomotor controlled?

Servomotors require a servo controller or a motion control unit that processes set values and precisely controls the movement via feedback. Typical fieldbus systems such as EtherCAT, CANopen or PROFINET are used for this.

Are there different types of servomotors?

Yes, there are different designs, depending on the application:

– AC servomotors: Most common design, ideal for industrial applications

– DC servomotors: More compact, simpler control

– Linear servomotors: Generate linear instead of rotary movements

How long does a servomotor last?

With the right design and care, lifetimes of 20,000 to 40,000 hours or more are common. The exact service life depends heavily on the load, environment and maintenance.

What protection classes are there for servomotors?

– IP20-IP40: For dry indoor areas

– IP54-IP65: For dusty or damp industrial environments

– IP67: For contact with splash water or cleaning processes

How do I choose the right servomotor?

The selection depends on:

– Load torque and speed

– Required precision

– Installation space

– Ambient conditions

– Interfaces to the control unit

We will be happy to answer any questions you may have and look forward to hearing from you.

You can reach us Mon – Thu from 8 am to 5 pm and Fri from 8 am to 2 pm.