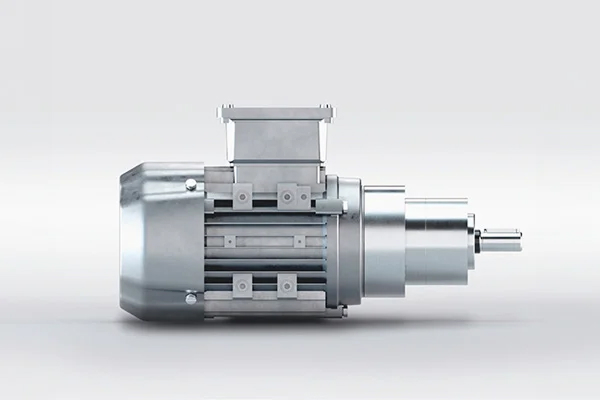

Asynchronous motors

Reliable technology for versatile applications

Asynchronous motors, also known as three-phase asynchronous motors or asynchronous machines, are proven drives that are characterized by their robustness, high efficiency and long service life. They are optimized for a variety of industrial applications and offer an economical solution for a wide range of applications.

With sizes from 56 mm to 315 mm, protection classes up to IP66 and a voltage range from 230V to 690V AC, they can be flexibly adapted to different requirements. The power ranges extend from 0.09 kW to 500 kW – ideal for applications from smaller machines to powerful industrial systems.

Thanks to their simple design and low-maintenance technology, asynchronous motors are a reliable choice for continuous operation. They can be easily integrated into existing systems and offer excellent value for money.

From 56 mm to 315 mm

Up to IP66

From 230V to 690V AC

From 0.09 kW to 500 kW

b-drives offers BLDC motors with diameters from 42 mm to 130 mm, protection classes up to IP65 and voltage ranges from 24V DC to 60 V DC. The power ranges from 10W to 3 kW, enabling individual solutions for industrial applications.

How does an asynchronous motor work?

Asynchronous motors work according to the principle of electromagnetic induction. The stator generates a rotating magnetic field that induces a voltage in the rotor. This causes the rotor to move. Unlike synchronous motors, the rotor always runs at a slightly lower speed than the magnetic field – hence the term “asynchronous”.

This design has decisive advantages: Asynchronous motors do not require brushes or slip rings, making them virtually maintenance-free. The robust design makes them particularly durable, even under demanding conditions. Their speed can be flexibly controlled with a frequency inverter, which enables a high degree of adaptability to different operating requirements.

Low-wear technology for long-term use

Reliable operation even under high loads

Thanks to brushless design

by frequency inverters for asynchronous motors

Typical areas of application for asynchronous motors

The versatility of asynchronous motors makes them a preferred choice in many industries. Their robust properties and high efficiency ensure a reliable drive in a wide range of applications.

Asynchronous motors have become indispensable in numerous branches of industry due to their reliability and long service life. They combine robust technology with economic efficiency and are suitable for a wide range of requirements.

They drive conveyor systems and transport systems and ensure smooth processes in production facilities.

Asynchronous motors are ideal for applications that require a constant speed and high efficiency, such as in ventilation systems or industrial pumps.

They are used in production systems as well as in lifting and conveyor technology where precise and reliable movements are required.

In air conditioning and ventilation systems, they ensure energy-efficient operation, while they are used in generators to produce electricity.

Here they are used in irrigation systems, mills and conveyor belts, where they ensure reliable and long-lasting operation.

Frequently asked questions about BLDC motors

What is an asynchronous motor?

How does the speed control of an asynchronous motor work?

What protection class do I need for my motor?

There are different protection classes depending on the environment and area of application:

- IP55: Protection against dust and splash water – ideal for standard industrial applications.

- IP65: Complete protection against dust and water jets – suitable for demanding environments.

- IP66: Maximum protection against dust and strong water jets – recommended for particularly harsh conditions.

In which sectors are asynchronous motors used?

Asynchronous motors can be found in almost every industry, including:

- Production & mechanical engineering: Drives for machine tools, cranes and conveyor systems

- Building technology: control of ventilation and air conditioning systems

- Agriculture: use in irrigation systems and animal feed processing

- Automation technology: use in transport systems and robotics

What do I need to consider when buying an asynchronous motor?

When purchasing an asynchronous motor, there are several factors to consider in order to make the optimal choice for your application. These include the desired output in kW, the size, the protection class and the speed control using a frequency inverter. If you want to buy an asynchronous motor, you should also pay attention to whether a single-phase or three-phase motor is required.

Get your individual consultation now and find the right asynchronous motor for your application!

We will be happy to answer any questions you may have and look forward to hearing from you.

You can reach us Mon – Thu from 8 am to 5 pm and Fri from 8 am to 2 pm.